News

-

Boost Your Logistics Efficiency with Durable Roll Container

In today’s fast-paced supply chain environment, efficient material handling is the cornerstone of operational success. Enter Roll Containers—the versatile, durable solution designed to streamline workflows, enhance safety, and maximize space utilization. Whether you’re managing a warehouse, manuf...Read more -

Racking and Storage Solutions for Efficient Warehouse Management

Efficient warehouse management relies heavily on selecting the right racking and storage systems. Proper storage maximizes space, improves safety, reduces picking time, and helps maintain accurate inventory. The type of racking chosen should depend on the size, weight, and handling needs of diffe...Read more -

What Is High Density Warehouse Racking

High density warehouse racking is a racking system designed to maximize warehouse space utilization. It achieves higher storage capacity per unit area by reducing the number of aisles and increasing the storage density of goods. This type of racking is suitable for scenarios with large storage ca...Read more -

Advantages and Disadvantages of Very Narrow Aisle Pallet Racking

The Very Narrow Aisle (VNA) Pallet Racking System is a highly efficient logistics and warehouse storage solution that maximizes vertical and horizontal space. By reducing aisle widths to as narrow as 1.6 meters and supporting rack heights up to 15 meters, VNA systems can significantly increase st...Read more -

China Radio Shuttle Pallet Racking Manufacturers-Aceally

In the evolving landscape of modern warehousing and logistics, efficiency and smart automation have become the pillars of success. Among the many innovations driving this transformation, Radio Shuttle Pallet Racking Systems stand out as one of the most intelligent, space-saving, and high-density ...Read more -

Boltless shelving, also known as rivet shelving, is a popular type of industrial storage system that stands out due to its simple, efficient design. Unlike traditional shelving units that require bolts, screws, or specialized tools for assembly, boltless shelving systems rely on a rivet-and-slot ...Read more

Boltless shelving, also known as rivet shelving, is a popular type of industrial storage system that stands out due to its simple, efficient design. Unlike traditional shelving units that require bolts, screws, or specialized tools for assembly, boltless shelving systems rely on a rivet-and-slot ...Read more -

Application of Double Deep Rack System

The double deep rack system is a highly efficient storage solution that has gained significant popularity in modern warehousing and logistics. This system features two levels of pallets stored in each bay, effectively doubling the storage density compared to traditional single-deep rack systems....Read more -

What’s the Difference Between Shelves and Racks

The difference between shelves and racks lies mainly in their structure, function, and how they are used. Here’s a clear explanation without using a table: 1. Definition Shelves refer to flat horizontal surfaces—usually layered—used for storing or displaying items. They are often fixed to ...Read more -

Xiamen Port Empowers Wang Shengchun’s Family Business to Lead Cross-Border Trade and Urban Growth

Taking Xiamen as a Port, the Family Enterprise Crafts a Cross-border Saga and Paves the Way for a New Chapter of Urban Development—— Wang Shengchun At the site of the “Lu Hang Zhi Yuan” Ideal and Belief Education Training Class for Private Economy Personnel in Xiamen Cit...Read more -

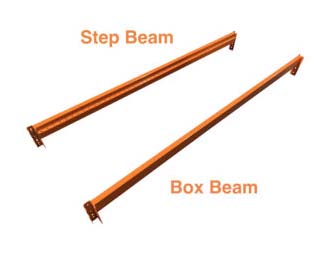

Step Beam vs Box Beam for Racking

When selecting beams for pallet racking systems, two common options are step beams and box beams. Each has unique characteristics, and understanding their advantages and disadvantages can help you choose the best fit for your warehouse needs. Step Beam A step beam features an inward step or ledg...Read more -

Proper tire storage is essential to maintain tire quality, prevent deformation, and ensure safety. When storing tires, especially in warehouse settings, the use of heavy-duty tire storage racks offers significant advantages. Here’s a comprehensive guide on how tires should be stored, integrating ...Read more

Proper tire storage is essential to maintain tire quality, prevent deformation, and ensure safety. When storing tires, especially in warehouse settings, the use of heavy-duty tire storage racks offers significant advantages. Here’s a comprehensive guide on how tires should be stored, integrating ...Read more -

How to Determine Cantilever Rack Capacity

Determining the safe capacity of a cantilever rack involves careful consideration of several practical factors without relying solely on formulas or tables. Here’s how to approach it systematically: 1. Start with Manufacturer Specifications Load Rating Labels: Check for a visible manufacturer’s ...Read more