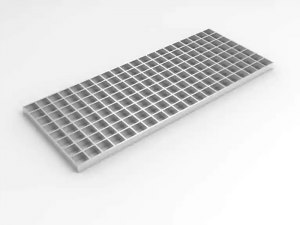

Galvanized Steel Grating for Mezzanine Floor

Galvanized steel grating is a practical and reliable flooring solution for mezzanine floors and industrial platforms. Designed with an open-grid structure, it provides stable load support while allowing airflow, light penetration, and visibility between levels. This type of grating is widely used in warehouses and industrial facilities where safety, durability, and functionality are required.

With its galvanized surface treatment, the steel grating offers basic corrosion protection, making it suitable for indoor mezzanine applications and controlled industrial environments.

Heavy-Duty Steel Grating Structure

This mezzanine floor grating is manufactured using steel bearing bars and cross bars that are securely welded together to form a rigid and uniform grid.

Key structural characteristics include:

-

Flat steel bearing bars designed to support personnel and stored goods

-

Cross bars welded at consistent intervals for structural stability

-

Square or rectangular openings for even load distribution

-

Optional serrated bearing bars to improve slip resistance

The precise grid layout ensures strength while maintaining a lightweight, open design compared to solid flooring materials.

Key Advantages for Mezzanine Floors

High Load-Bearing Performance

The steel grating structure is capable of supporting typical mezzanine floor loads, making it suitable for walkways, working platforms, and storage access areas.

Anti-Slip Surface Option

Serrated bearing bars can be selected to enhance traction, reducing the risk of slipping on elevated platforms.

Open Grid Design

The open construction allows:

-

Natural light to pass through multiple levels

-

Air circulation to reduce dust and heat buildup

-

Visibility between floors for safer warehouse operations

Galvanized Surface Protection

The galvanized finish helps protect the steel from corrosion and wear in daily industrial use, reducing maintenance requirements over time.

Typical Applications

Galvanized steel grating is commonly used in:

-

Warehouse mezzanine floors

-

Mezzanine racking walkways

-

Industrial platforms and service areas

-

Distribution centers and logistics facilities

Its combination of strength and ventilation makes it especially suitable for multi-level warehouse layouts.

Technical Specifications

| Item | Description |

|---|---|

| Material | Carbon steel |

| Surface Finish | Galvanized |

| Grid Type | Square or rectangular |

| Bearing Bar Type | Flat bar / Serrated flat bar |

| Bearing Bar Thickness | 3–6 mm (customizable) |

| Panel Size | Standard or custom sizes available |

| Installation Method | Bolted or clipped to mezzanine structure |

Specifications can be customized based on project requirements.

Steel Grating vs Other Mezzanine Flooring Options

Compared to Wooden Planks

Steel grating offers higher load capacity, improved fire resistance, and a longer service life with minimal deformation.

Compared to Solid Steel Plates

Steel grating is lighter in weight and provides better airflow and drainage, making it easier to maintain and safer for elevated use.

Installation & Maintenance

Steel grating panels are designed for straightforward installation on standard mezzanine beams. Panels can be fixed using bolts or mounting clips, allowing for easy removal or replacement if required.

Routine inspection and simple cleaning are usually sufficient to maintain performance, thanks to the galvanized surface finish.

Reliable Mezzanine Flooring Solution

Galvanized steel grating is a proven flooring choice for mezzanine floors where strength, safety, and ventilation are essential. Its durable construction and practical design make it suitable for long-term industrial use.

Request a Quote

Looking for a customized steel grating solution for your mezzanine floor?

Contact us today to discuss load requirements, panel sizes, and installation options. Our team can provide professional support for your warehouse or industrial platform project.